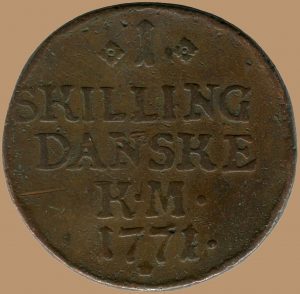

Kongsberg

Kongsberg Type 1

The Kongsberg mintage of the 1 skilling 1771 was initiated in late 1782, more than 11 years after the first 1771 skilling coins were struck at the Altona Mint. The mintage plan was quite ambitious, with a goal of producing 1.920.000 coins (20.000 Rigsdaler). Although the first 23.184 coins were delivered in April 1783, the production quickly came to a halt due to poor copper quality.

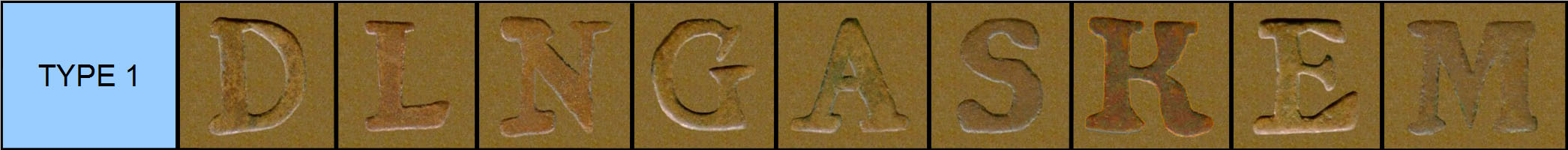

We believe Kongsberg Type 1 was minted during this early period. It’s a small production series of only 2 reverses, K101 and K102, and their corresponding obverses. The dies were made by Anders Lunde and have a characteristic font, quite different from the fonts used by Johan Ephraim Bauert at the Copenhagen Mint and Johan Henrik Wolff at the Altona Mint.

While K101 is uncommon, we suspect that the many known K102 coins could imply that this variation was also part of the continued mintage during the second half of 1784. At least the corresponding obverses of K101 and K102 were used during this period in combination with Kongsberg Type 2 reverses.

Fonts

Kongsberg Type 2

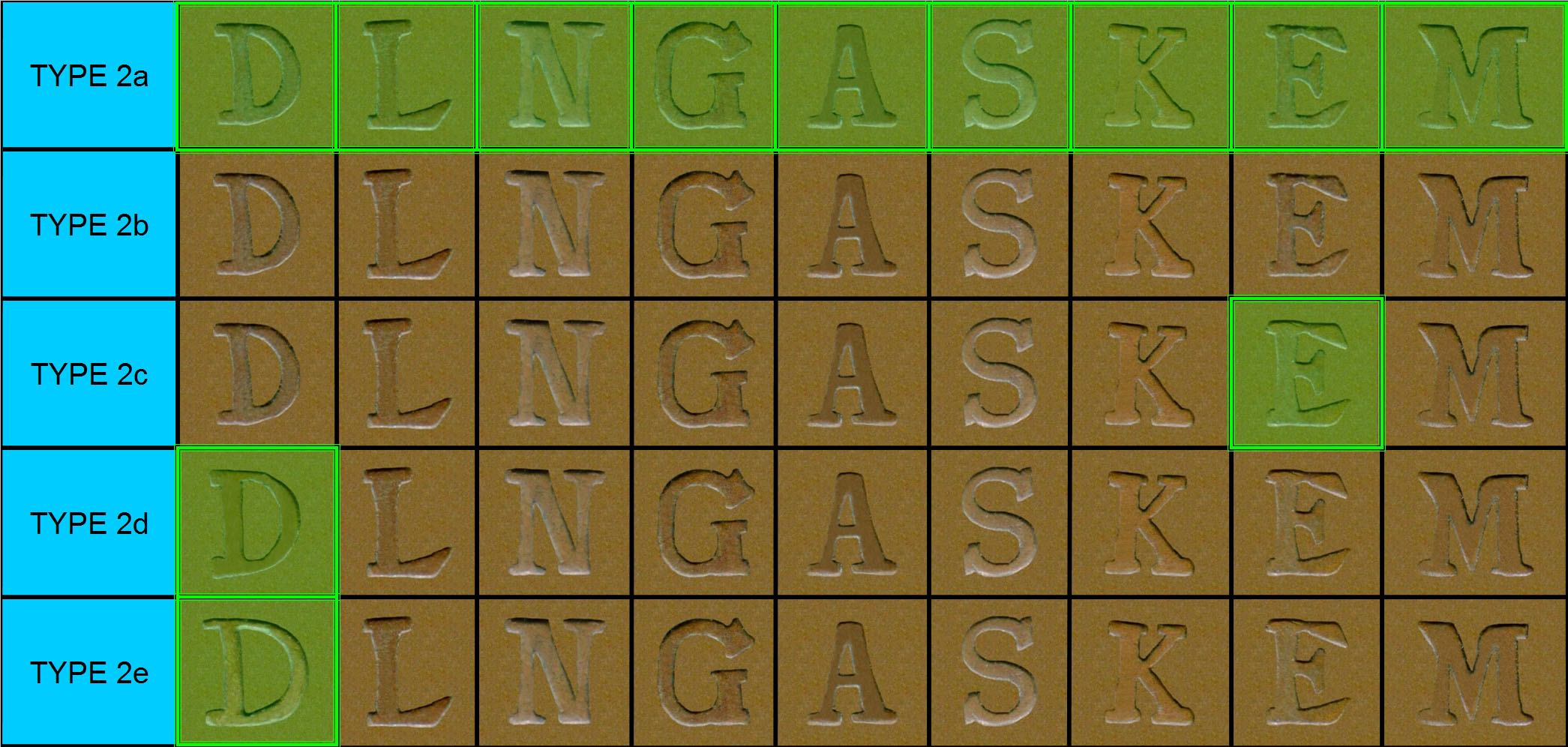

Lunde was probably quickly instructed to adjust his fonts to look more similar to the fonts used for the Altona and Copenhagen mintage. We believe that he made the Kongsberg Type 2a dies during the summer of 1784 as the Mint planned to ramp up the production quite substantially. They had received copper platelets from Sweden and were now ready to continue the production process. The Kongsberg Type 2a consists of 14 pairs of dies that were used during the second half of 1784.

The copper quality at the Kongsberg Mint was notoriously poor and unclean during the whole mintage period. After the first 194.880 coins of Type 2a were minted, the Kongsberg Mint received 240.000 blank copper planchets from Copenhagen in August 1784. These planchets contained a more normal copper grade, and were immediately used in the production of Kongsberg Type 2b and Type 2c. As the size of these planchets was larger than the standard “1 skilling Kongsberg” size, these dies had to be adjusted to fit a larger diameter.

The only difference between Type 2a and Type 2b is the coin size as the fonts are identical. Kongsberg Type 2b consists of two reverses, K231 and K232. From this variation, we can see a development into Type 2c where the “E” has a bottom line that rises more linearly from the stem. The six Type 2c reverses were also custom made for the copper planchets, and we have many examples of die mixes between Type 2b and Type 2c.

After the copper planchets were depleted, the Kongsberg Mint reverted back to using Type 2a dies in late October 1784. At this time, they probably still had 8 to 10 pairs of them warehoused. In addition, Lunde continued his die production of “normal” sized dies. However he made a small change to the “D” to a somewhat larger letter (Kongsberg Type 2d). As there were no preferences of using older dies over the more recent, we have very many examples of die mixes between Type 2a and Type 2d. Later, probably during December 1784, this development continued with an even larger “D” in Kongsberg Type 2e.

It should be noted that Lunde probably wasn’t the only die cutter working with the Kongberg Type 2 mintage: In June 1783, Nicolai Wilhelm Wrigth joined the Kongsberg Mint as Lunde’s apprentice, and he quickly made progress in the art of die cutting. During the summer of 1784, he clearly impressed his superiors at the Danish Treasury Administration by his test dies and was encouraged to continue assisting Lunde in his work. From a test die he made during this period (see picture below), we can see strong similarities to the obverses KO221, KO263, KO268 and KO269 that were made in very late 1784 or early 1785. (Wrigth made his test die with extra “stems” or “waves” on top of the crown circlet/base.) We assume he has made some of the reverses too, but here we have no leads to distinguish which ones.

While the Kongsberg Type 2 mintage was hectic during late 1784 with 100.000 coins minted every week, the pace slowed down considerably into 1785. In fact it practically came to a complete stop with only 40.000 coins delivered by August 1785. Altogether, there were made 36 pairs of dies during the Kongsberg Type 2 mintage.

Fonts

Kongsberg Type 3

For a change, it’s the obverses that distinguish Type 3 from the other Kongsberg variations. The backdrop for the obverse change was most likely a poorly made Rigsdaler Species for which Anders Lunde was harshly criticized by the Treasury Administration. They even sent him a die imprint in lead, made by an apprentice in Copenhagen (Georg Valentin Bauert), to show him how to do his job. From the picture below, we can see that the crown now was altered to make it flatter and broader, in line with Bauert’s example.

At the reverse side, we have a development to a slimmer “S” (marked in green below). The Kongsberg Type 3 mintage of close to 800.000 coins was done during the fall and winter of 1785/1786. Most of these were delivered before year end 1785, but the last 80.000 coins were delivered in June and October 1786. There was altogether made 16 pairs of dies for the Kongsberg Type 3 mintage.

Fonts